Product Engineering From an idea to being popular in stores.

Product engineering involves the comprehensive process of designing, developing, and managing products throughout their lifecycle. This discipline integrates various engineering principles with design and manufacturing processes to ensure that products meet market demands, function efficiently, and can be produced cost-effectively. It encompasses everything from initial concept and design to development, testing, deployment, and maintenance.

What is the Process?

Ideation and Concept Development

Generating ideas and developing initial concepts based on market research, customer feedback, and business goals.

Design and Prototyping

Creating detailed designs and building prototypes to visualize and test product functionality, aesthetics, and user experience.

Engineering and Development

Turning prototypes into fully functional products. This stage involves selecting materials, defining manufacturing processes, and ensuring all technical specifications are met.

Testing and Validation

Conducting rigorous testing to validate product performance, safety, and compliance with industry standards. This may include beta testing with real users.

Manufacturing and Production

Scaling the product for mass production, ensuring quality control, and optimizing manufacturing processes for efficiency and cost-effectiveness.

Deployment and Launch

Bringing the product to market, which involves marketing, distribution, and sales strategies.

Maintenance and Support

Providing ongoing support, addressing any issues, and collecting feedback for future improvements.

Generating ideas and developing initial concepts based on market research, customer feedback, and business goals.

Creating detailed designs and building prototypes to visualize and test product functionality, aesthetics, and user experience.

Turning prototypes into fully functional products. This stage involves selecting materials, defining manufacturing processes, and ensuring all technical specifications are met.

Conducting rigorous testing to validate product performance, safety, and compliance with industry standards. This may include beta testing with real users.

Scaling the product for mass production, ensuring quality control, and optimizing manufacturing processes for efficiency and cost-effectiveness.

Bringing the product to market, which involves marketing, distribution, and sales strategies.

Providing ongoing support, addressing any issues, and collecting feedback for future improvements.

How We Solve?

Collaborative Ideation

Working closely with clients to understand their vision and translate it into viable product concepts.

Advanced Prototyping

Utilizing state-of-the-art tools and technologies to create realistic prototypes for thorough testing and refinement.

Comprehensive Testing

Implementing extensive testing protocols to ensure that every product meets stringent quality and performance standards.

Efficient Production Management

Streamlining manufacturing processes to reduce costs and time-to-market while maintaining high-quality standards.

How We Solve?

Collaborative Ideation

Working closely with clients to understand their vision and translate it into viable product concepts.

Advanced Prototyping

Utilizing state-of-the-art tools and technologies to create realistic prototypes for thorough testing and refinement.

Comprehensive Testing

Implementing extensive testing protocols to ensure that every product meets stringent quality and performance standards.

Efficient Production Management

Streamlining manufacturing processes to reduce costs and time-to-market while maintaining high-quality standards.

What are the Key Points?

Customer-Centric Design

Innovative Solutions

Leveraging the latest technologies and industry trends to create cutting-edge products.

Scalability and Flexibility

Designing products that can be easily scaled and adapted to meet changing market demands.

Sustainability

Prioritizing sustainable practices in product design and manufacturing to minimize environmental impact.

Quality Assurance

Ensuring every product meets high standards of quality, safety, and reliability through rigorous testing and validation.

What Technology Do We Use?

Computer-Aided Design

Building agile systems and processes that can quickly adapt to changing market conditions and technological advancements.

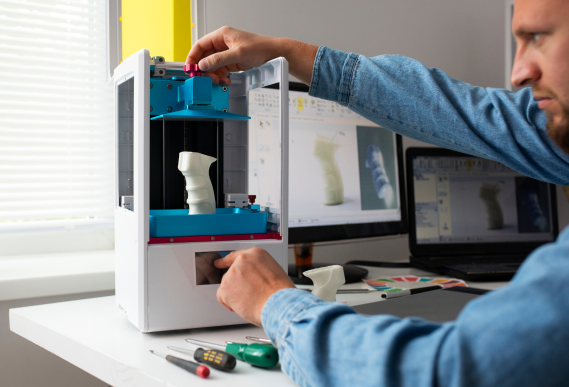

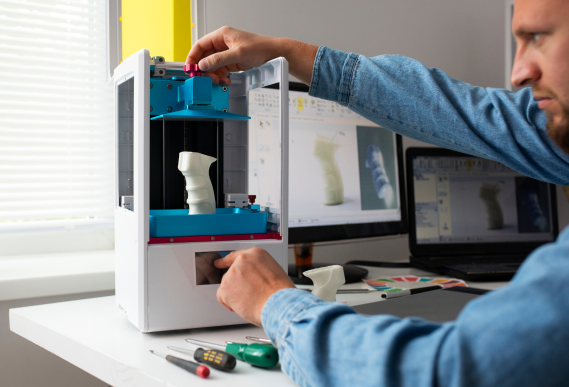

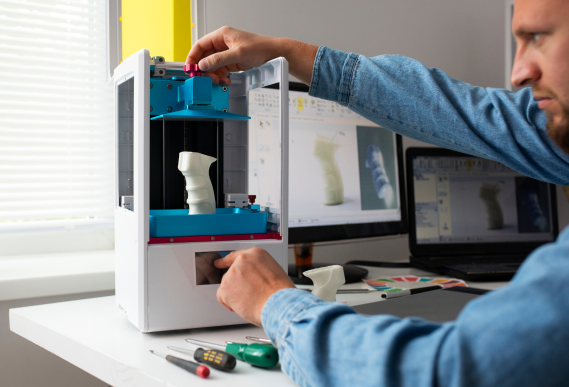

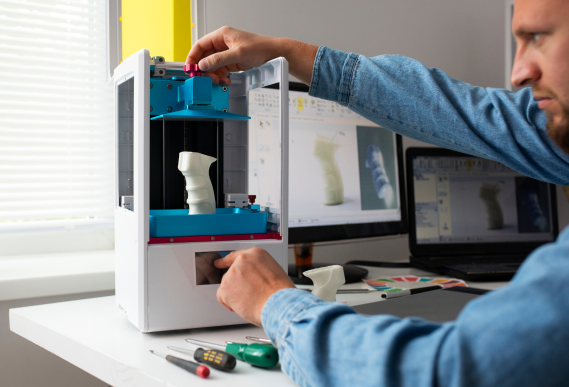

3D Printing

To create rapid prototypes and small-batch production runs.

Internet of Things (IoT)

For smart, connected product features and real-time data collection.

AI & Machine Learning

To enhance product functionality, user experience, and predictive maintenance.

Advanced Materials

Utilizing cutting-edge materials for improved performance, durability, and sustainability.

Computer-Aided Design

Building agile systems and processes that can quickly adapt to changing market conditions and technological advancements.

3D Printing

To create rapid prototypes and small-batch production runs.

Internet of Things (IoT)

For smart, connected product features and real-time data collection.

AI & Machine Learning

To enhance product functionality, user experience, and predictive maintenance.

Advanced Materials

Utilizing cutting-edge materials for improved performance, durability, and sustainability.

What Technology Do We Use?

Computer-Aided Design

Building agile systems and processes that can quickly adapt to changing market conditions and technological advancements.

3D Printing

To create rapid prototypes and small-batch production runs.

Internet of Things (IoT)

For smart, connected product features and real-time data collection.

AI & Machine Learning

To enhance product functionality, user experience, and predictive maintenance.

Advanced Materials

Utilizing cutting-edge materials for improved performance, durability, and sustainability.

Computer-Aided Design

Building agile systems and processes that can quickly adapt to changing market conditions and technological advancements.

3D Printing

To create rapid prototypes and small-batch production runs.

Internet of Things (IoT)

For smart, connected product features and real-time data collection.

AI & Machine Learning

To enhance product functionality, user experience, and predictive maintenance.

Advanced Materials

Utilizing cutting-edge materials for improved performance, durability, and sustainability.